By Dan Marshall on Aug 28, 2020 1:49:11 PM

The Cloudcover

I once had to specify some air filters because, well...

However, I couldn't find an industry consensus on the airflow needed…so I tested them all.

The Storm

At Martin Engineering, we use - among other things - an Insertable Dust Collector Air Cleaner to handle dust at transfer points. Without going into product details (you can click here if you want to see that stuff), I will just say that you need to know how much air is being generated in the transfer point to make sure your air cleaner is big enough to keep all the air (and dust) inside the transfer point. I knew that if you could control the air, you could control the dust. I figured I could save a trip and just calculate the airflow. However, every source predicted different airflows for the same application. I was spinning into a spiral of despair, thinking there would be no way to solve this problem.

The Clouds Break

Then it hit me, “why don’t you take a few applications, measure the geometry, calculate the airflows, and then measure them?” The theoretical values could be compared to the measured values, and the most accurate method could be found. I made a few calls, called in a few favors, bought a few lunches, promised a few co-authoring rights, but finally got access to three transfer points in an old coal plant.

Road Trip Time!!!

I loaded my equipment into the truck and drove to this plant. These three transfer points were as different from each other as possible. I spent the day crawling all over that plant and capturing the geometry of each transfer point. I also measured the actual airflow of each transfer point. At the end of the day, after I had scrubbed coal from every pore, I calculated and compared each airflow with reality. In the worst case, the calculated values diverged from reality by 64.3%. In the best case, using the method shown in our Foundations™ book, the values only varied by 7.8%. I also measured the airflows at my target application on my way home.

I corrected for the slight variance and specified an air cleaner. I learned something powerful. The different calculation methods are thorough and will give you values with varying degrees of accuracy, but they cannot account for everything. Through it all, one calculation method was accurate 100% of the time.

I had to drive, get very dirty, and taste airborne coal dust, but I got completely accurate numbers. Though you do not always have the luxury, there is no substitute for actually seeing an application in the bulk solids industry. That is why I love working for Martin Engineering, the experts are not afraid to get dirty to solve your problems. From that day forward, I never passed up an opportunity the see an application “in the wild.”

In my time at Martin, I have contributed to several chapters in our Foundations™, the Practical Resource for Cleaner, Safer, and More Productive Dust & Material Control Book. I thought this chapter on airflow might be of interest to you.

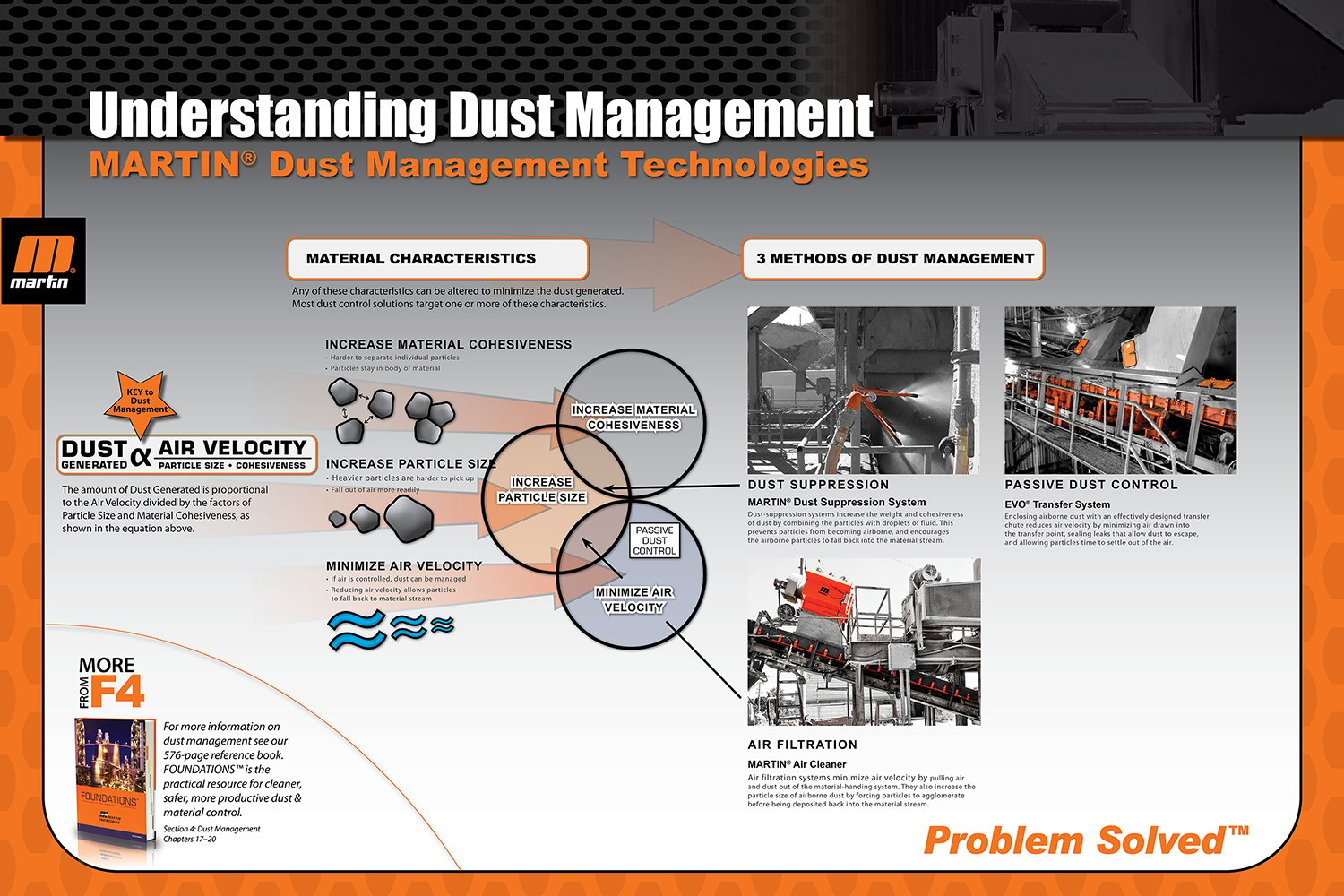

Below is a graphic I often refer to when I get into talks on controlling airflow and dust, I hope it is helpful to you.

comments