By Tyler Bates on Nov 13, 2020 10:59:21 AM

An issue I often hear about in my customer service role is how quickly our customers' conveyor skirting wears out, requiring them to frequently adjust it down. This always makes me question what their application looks like and why it would be wearing out so soon when it is designed to last much longer. In most cases, it is always the same issue of an incorrect application. They are using our skirting as a barrier to keep material on the belt. This is not the intention of conveyor skirting.

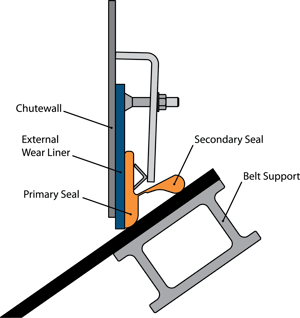

The chutewall or wearliner needs to be put in place to keep material on the belt. Skirting should be installed with the intention of sealing that conveyor on the outer edges, keeping the dust from escaping and keeping your conveyor airtight and therefore running much more efficiently.

If you can get your conveyor sealing systems set up with the proper belt support, wearliner, and skirting, the maintenance of constantly changing out the rubber skirting goes away and so does the dust and clean up that comes with it.

What To Do If You Have This Problem

One of the best ways to resolve it is using external wearliner which eliminates the need to enter a confined space for maintenance as it can be adjusted from the outside of the conveyor right along with the skirting.

Sealed & Satisfied

I received a call from a customer not too long ago that was having product spill off of the conveyor when it was being loaded. The customer was telling me how the skirting they just purchased was flipping out and not holding the material on the conveyor. I think a lot of customers want skirting to be an all-purpose product that keeps everything sealed up on the conveyor, but that is not something it can handle. After talking more with the customer and seeing their application, we determined that there was not enough chutewall or wearliner in place to actually hold material on the belt and for the skirting to do its job of sealing that conveyor belt. We were able to get them some external wearliner to install on their conveyor which gave them the correct product to hold material on their belts and it allowed the skirting to then seal that conveyor so no air was escaping which in turn helped to keep that conveyor from having any spillage or dust issues. The customer was very pleased with the results, and it just took a little understanding of what our skirting is supposed to do and how it works with the conveyor wall or wearliner to help seal everything up and keep material from escaping the conveyor belt.

comments