By Dan Marshall on Aug 26, 2022 11:06:13 AM

It's back...another edition of Good, Bad, Ugly where I detail some of the interesting things I have seen on the bulk materials handling scene!

The Good

When I saw this I thought, “this is how a tail pulley is supposed to look.” I was amazed by how clean it was. There was no dust, carryback, and spillage. The paint was unchipped and there was no rust in sight. The only complaint I have is the exposed pinch points.

Just from glancing, you would think this belt has never carried any material. Guess what, you would be right. This was a staged picture of a conveyor that had yet to be put in service. The reality is that an active conveyor looks much worse - it is just the nature of the business.

The Bad

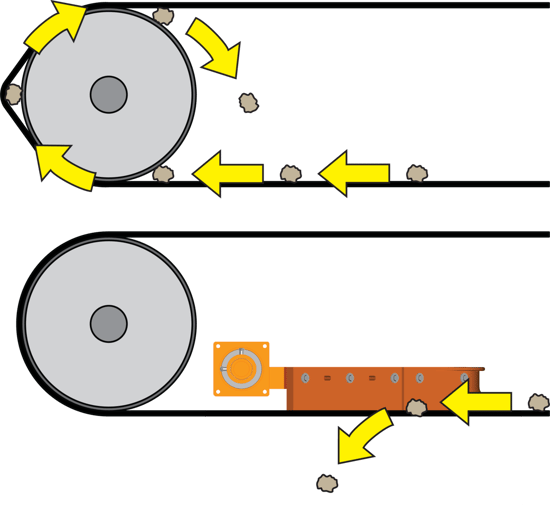

When I saw this, I instantly thought, “something is dropping material from the underside of the belt and it is traveling straight to the tail.” Given enough time and neglect, you will bury the tail.

Tail pulleys are a vital component of a belt conveyor system. This component is subjected to danger whenever any piece of material falls onto the return side of the conveyor belt.

Occasionally along its return run, the belt will collect and carry a lump of spilled material to the tail pulley on the non-carrying side of the belt. If these objects are not removed from the belt, they can become trapped between the pulley and the belt, causing damage to either or both.

The entrapment of anything between the belt and the pulley can cause significant damage to a conveyor system. When fugitive material is trapped between the belt and the pulley, one or more failures are likely to occur:

- Degradation of the Fugitive Material

If material falls, it will break up into smaller parts and be carried between the belt and the pulley. Material trapped in this location can allow the belt to slip against the pulley, causing the non-carrying, underside of the belt to wear. Even small particles and fines can wear and grind away on the less durable, easily-damaged surface of the belt. Furthermore, material that builds up on tail pulleys will cause the belt to wander, damaging the belt edge and/or the conveyor structure.

- Failure of the Belt

Any material entrapped between the pulley and the belt has the potential for forcing its way out through the belt's top cover, particularly if the material has sharp edges. This creates an uneven belt surface and can be a starting point for longitudinal and profile rips, holes, or edge gouges along the length of the belt. - Failure of the Pulley

If the material and the belt do not fail, the face of the tail pulley is likely to be damaged. A damaged pulley will lead to belt misalignment, belt damage, or pulley slippage.

The biggest problem arising from material entrapment is that it's a repeating phenomenon. Once a piece of material reaches the pulley, it can be pinched between the belt and pulley, carried around the pulley’s rotation, and then ejected back onto the return side of the belt. Once there, it will travel toward the pulley to be consumed again.

In essence, if it initially fails to break something, the lump will keep trying until it gets it right or is removed from the belt. If the material is strong enough, it could destroy the entire tail pulley section of a belt conveyor system.

In essence, if it initially fails to break something, the lump will keep trying until it gets it right or is removed from the belt. If the material is strong enough, it could destroy the entire tail pulley section of a belt conveyor system.

It's truly the gift that keeps on giving. ↓

All of this damage could be prevented if a simple  is placed in front of the tail on the top side of the return belt, right in front of the tail pulley. Or, better yet, fix the hardware that is spilling material.

is placed in front of the tail on the top side of the return belt, right in front of the tail pulley. Or, better yet, fix the hardware that is spilling material.

The Ugly

Every industrial facility I have ever been to has a dark, ugly secret. I call it “the boneyard.” It is a spot, usually at the back of the facility (away from prying eyes), where every piece of broken or replaced hardware winds up. The facilities are not sloppy or lazy, they just do not have the money, time, or manpower to dispose of EVERY individual component right away. Many facility maintenance personnel have a little voice in the back of their brain saying, “don’t throw THAT away, you never know when you might need part of it.” A perfect example is an idler set that was replaced because the frame was bent. If another idler has a bearing that goes bad and it may take days to get a new one, a maintenance person could “borrow” an idler can from the boneyard in a pinch. They will, of course, replace the can when the new one arrives. It shows up and the maintenance person says, “throw it in the boneyard, I will replace it when I have the time.” We all know how this story ends.

It may sound like a horrible place, but it is quite interesting. You can see the entire history of a facility by traveling around the boneyard with a maintenance person looking for something. They will regale you with tales of plant refits, difficult projects, humorous antics of a coworker, close calls, failed projects, and successes. All because they see something that is a reminder.

Chances are your facility probably has a boneyard. If you want to experience some fun history, offer a senior maintenance person assistance in finding a part in the “back lot.”

comments