Problem

The Hunter Cement Plant in New Braunfels, Texas - owned and operated by Martin Marietta - reports annual production of 2.3 million TPY (2 million MTPY). The facility was experiencing transfer chute clogging and conveyor belt backups from wet fines and aggregate on its partially-covered D-07 conveyor. Heavy seasonal rain caused serious spillage issues and accumulation in the chute, which halted plant production. When the material flow ceased, 2-3 workers used air lances and pneumatic jackhammers fitted with 8-foot long bits, which required 6-8 hours to clear the obstruction, posing a potential workplace hazard and increasing operating costs.

Solution

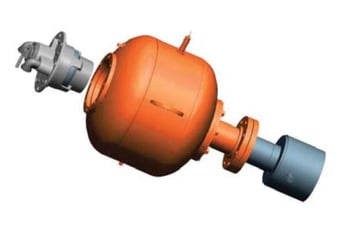

Martin technicians installed five 70-liter Martin® Hurricane Air Cannons on two levels. The 94 lb. (43 kg) tanks were suspended from the tower frame by steel cords and connected to the plant’s existing compressed air system. Strategically placed along the chute, the units fire a blast of air at up to 120 PSI (8.27 BAR) through a fan jet nozzle with a 12-inch (305 mm) wide mouth, covering an area of up to 22.6 cubic feet (640 cubic liters). Pointed in a downward angle, this configuration effectively cleared obstructions and assured proper material flow to minimize unscheduled downtime and reduce the need for manual cleanup.

Results

Six months after the installation, plant managers report that the air cannons have significantly decreased the clogging and backup issues, resulting in continuous operation with minimal unscheduled downtime. The area around the chute now only needs routine cleanup and maintenance accompanying normally-scheduled inspections. “We were confident that the Martin team was going to come through,” Martin Marietta management concluded. “Like their other cannons in the plant, the equipment has worked out well. With the team’s consistently-attentive service, this has turned out to be a good solution.”