PROBLEM

The JEA coal-fired power plant in northern Florida was having chute clogging and spillage issues at the discharge zone of its limestone conveyor. The existing primary and secondary cleaners allowed uneven discharge of material, which clung to chute walls and caused clogging, requiring periodic downtime for adjustment. The blade edges wore quickly, causing enough carryback and spillage to encapsulate the cleaners. Labor costs to clean up fugitive material and the maintenance and replacement of equipment raised the cost of operation.

The JEA coal-fired power plant in northern Florida was having chute clogging and spillage issues at the discharge zone of its limestone conveyor. The existing primary and secondary cleaners allowed uneven discharge of material, which clung to chute walls and caused clogging, requiring periodic downtime for adjustment. The blade edges wore quickly, causing enough carryback and spillage to encapsulate the cleaners. Labor costs to clean up fugitive material and the maintenance and replacement of equipment raised the cost of operation.

SOLUTION

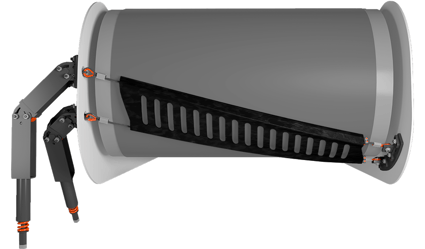

After thoroughly inspecting the operation, Martin technicians installed a CleanScrape® Cleaner. Installed diagonally across the discharge pulley, rather than at 90º like other cleaners, the uniquely designed blade is comprised of a matrix of tungsten carbide scrapers tensioned lightly by cables against the belt. Despite the extremely low contact pressure between the belt and cleaner to prevent damage to the belt or splices, the system has been shown to remove as much as 95% of potential carryback. In some operations, the cleaner has been so effective that secondary cleaners have been eliminated.

After thoroughly inspecting the operation, Martin technicians installed a CleanScrape® Cleaner. Installed diagonally across the discharge pulley, rather than at 90º like other cleaners, the uniquely designed blade is comprised of a matrix of tungsten carbide scrapers tensioned lightly by cables against the belt. Despite the extremely low contact pressure between the belt and cleaner to prevent damage to the belt or splices, the system has been shown to remove as much as 95% of potential carryback. In some operations, the cleaner has been so effective that secondary cleaners have been eliminated.

RESULTS

By the end of the 60-day trial, the CleanScrape® Cleaner outperformed expectations, and 120 days after installation, there has been no unscheduled downtime for adjustment or major cleanup. The material has a consistently centered discharge, meaning the wet and sticky limestone does not cling to the sides of the chute or cause clogging issues, reducing the need for manual cleaning. The cost of equipment replacements and labor have been drastically reduced. The customer has recently purchased two more units for other conveyors and is requesting capital funding to upgrade all coal transport systems.

By the end of the 60-day trial, the CleanScrape® Cleaner outperformed expectations, and 120 days after installation, there has been no unscheduled downtime for adjustment or major cleanup. The material has a consistently centered discharge, meaning the wet and sticky limestone does not cling to the sides of the chute or cause clogging issues, reducing the need for manual cleaning. The cost of equipment replacements and labor have been drastically reduced. The customer has recently purchased two more units for other conveyors and is requesting capital funding to upgrade all coal transport systems.

More Categories

- Material Spillage (42)

- Material Carryback & Belt Cleaning (34)

- Material Flow Problems (33)

- Dust & Material Spillage (30)

- Air Cannons (16)

- Conveyor Belt Component Damage (15)

- Dust (15)

- Safety (14)

- Conveyor Belt Mistracking (13)

- Belt Conveyor Safety (11)

- Basics of Belt Conveyor Systems (10)

- Dust Management (9)

- Vibration (9)

- Belt Conveyor System Maintenance (8)