Problem

This fuel-efficient kiln operates by alternating the firing of two shafts, so one shaft burns while the other acts as a fuel for exhaust gases. The heated gases leave the combustion chamber through arches opening into a crossover channel.

This fuel-efficient kiln operates by alternating the firing of two shafts, so one shaft burns while the other acts as a fuel for exhaust gases. The heated gases leave the combustion chamber through arches opening into a crossover channel.

But dust would adhere to the refractory in the arches, choking the flow of gases from one combustion chamber into the other. To maintain kiln efficiency, the plant was forced to shut down every three months to remove the dust buildup. Each outage would mean five to seven days of lost production—costly outages costing more than a quarter-million dollars a year.

Solution

The kiln manufacturer suggested installing air cannons between the vertical kiln piers. But lime company officials were skeptical about how well air cannons would work in the heated and dusty environment of the vertical kiln.

The kiln manufacturer suggested installing air cannons between the vertical kiln piers. But lime company officials were skeptical about how well air cannons would work in the heated and dusty environment of the vertical kiln.

To test performance, they agreed to a trial installation of four Martin® Air Cannons supplied by Martin Engineering. The elastomer-free construction of the Martin® Air Cannon valve provides long life and high performance in tough, high-temperature applications like lime kilns.

Results

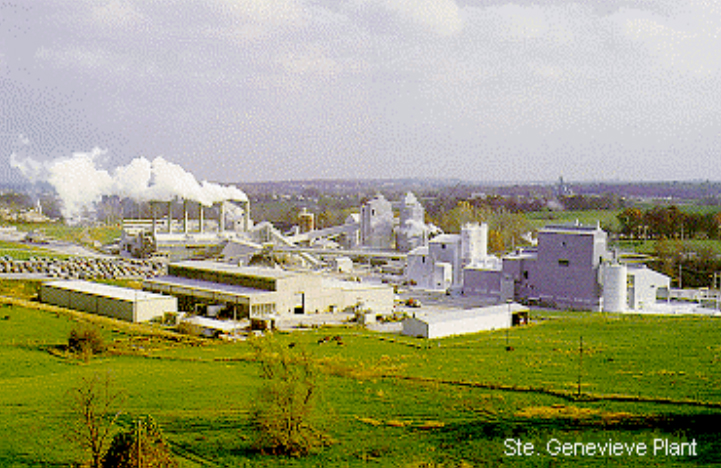

Within three months, the Ste. Genevieve Plant was forced to take another outage due to excessive material buildup, but not in the piers where the Martin® Air Cannons had been installed. The plant manager reported that those four arches were completely clean.

Within three months, the Ste. Genevieve Plant was forced to take another outage due to excessive material buildup, but not in the piers where the Martin® Air Cannons had been installed. The plant manager reported that those four arches were completely clean.

After reviewing these results, Mississippi Lime Company ordered the installation of an additional 16 air cannons. Now, a total of 20 Martin® Air Cannons are installed on a single level around the circumference of the kiln. The air cannons discharge during the 10-minute pre-heat cycle of each shaft, with each cannon firing once during that time. This removes the material accumulations without affecting the kiln’s combustion cycle.