Problem

Abrasive clinker would rapidly wear out the skirtboard sealing strips, creating a severe spillage problem at the conveyor’s loading zone. The sealing system required replacement every three weeks. Spillage presents many threats to profitability such as; potential for lost material, labor cost for cleanup, risk of injury, housekeeping issues, and increased threat of unexpected downtime.

Abrasive clinker would rapidly wear out the skirtboard sealing strips, creating a severe spillage problem at the conveyor’s loading zone. The sealing system required replacement every three weeks. Spillage presents many threats to profitability such as; potential for lost material, labor cost for cleanup, risk of injury, housekeeping issues, and increased threat of unexpected downtime.

Solution

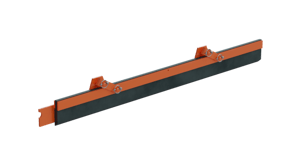

The Martin® Self Adjusting Skirting automatically adjusts to keep material on the belt and prevent loading zone spillage. Martin® Self Adjusting Skirting floats on the belt, maintaining sealing pressure without maintenance.

The Martin® Self Adjusting Skirting automatically adjusts to keep material on the belt and prevent loading zone spillage. Martin® Self Adjusting Skirting floats on the belt, maintaining sealing pressure without maintenance.

Supported on pressure arms between two steel plates, the rubber sealing strip rises and falls with fluctuations in belt travel to automatically maintain an effective seal. Martin® Self Adjusting Skirting is available in lengths up to 300 feet (91.4 m) to allow installation as one continuous strip without requiring a joint along a load zone.

Results

Martin Engineering provided personalized performance by tailoring the Martin® Self Adjusting Skirting to provide improved corrosion resistance while remaining within the customer’s budget. Installation was simple, straightforward, and required less time than other skirting.

Martin Engineering provided personalized performance by tailoring the Martin® Self Adjusting Skirting to provide improved corrosion resistance while remaining within the customer’s budget. Installation was simple, straightforward, and required less time than other skirting.

Sealing performance has improved over time, as the belt-to-rubber seal has "worn in" after installation. The customer has indicated plans to standardize Martin® Self Adjusting Skirting on all conveyors as time and budget allow.