Problem

The R.M. Schahfer Station coal-fired plant handles large quantities of synthetic gypsum as part of its process. The material is transported by conveyor, but the OEM system was experiencing fugitive material problems, with dust and spillage piling up and large chunks of gypsum falling off the belt in places. The belt was experiencing these issues at several points, forcing the maintenance team to spend significant man-hours to clean up the material and placing employees in a potentially hazardous situation by working in close proximity to a moving conveyor.

The R.M. Schahfer Station coal-fired plant handles large quantities of synthetic gypsum as part of its process. The material is transported by conveyor, but the OEM system was experiencing fugitive material problems, with dust and spillage piling up and large chunks of gypsum falling off the belt in places. The belt was experiencing these issues at several points, forcing the maintenance team to spend significant man-hours to clean up the material and placing employees in a potentially hazardous situation by working in close proximity to a moving conveyor.

Solution

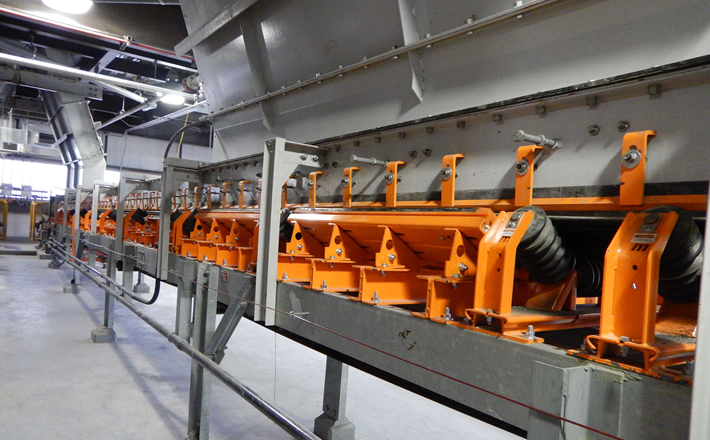

Martin Engineering technicians determined that inadequate belt support was the primary cause of the problem, allowing material to escape from the transfer point’s loading zone. They proposed installing a series of Slider Cradles and Impact Cradles with center support rollers to improve sealing, reduce fugitive material, and help prevent further belt damage. Martin Engineering supplies a wide variety of belt support solutions specifically engineered to prevent belt and mainframe damage and eliminate spillage of heavy materials.

Martin Engineering technicians determined that inadequate belt support was the primary cause of the problem, allowing material to escape from the transfer point’s loading zone. They proposed installing a series of Slider Cradles and Impact Cradles with center support rollers to improve sealing, reduce fugitive material, and help prevent further belt damage. Martin Engineering supplies a wide variety of belt support solutions specifically engineered to prevent belt and mainframe damage and eliminate spillage of heavy materials.

Results

With proper impact absorption and distribution, the force of the material transfer is cushioned and the gypsum’s momentum is better controlled, helping to prevent the violent disruption of the load that led to spillage. Instead, the Impact Cradles absorb much of the energy , and the Slider Cradles stabilize the material along the entire length of the loading zone. The sealing system now works far more effectively, and the cleanup time around the conveyor has been dramatically reduced. The customer is very happy with the results and is now able to direct the previously wasted manpower toward more productive tasks.

With proper impact absorption and distribution, the force of the material transfer is cushioned and the gypsum’s momentum is better controlled, helping to prevent the violent disruption of the load that led to spillage. Instead, the Impact Cradles absorb much of the energy , and the Slider Cradles stabilize the material along the entire length of the loading zone. The sealing system now works far more effectively, and the cleanup time around the conveyor has been dramatically reduced. The customer is very happy with the results and is now able to direct the previously wasted manpower toward more productive tasks.