By Niki Andris on Nov 12, 2021 2:32:12 PM

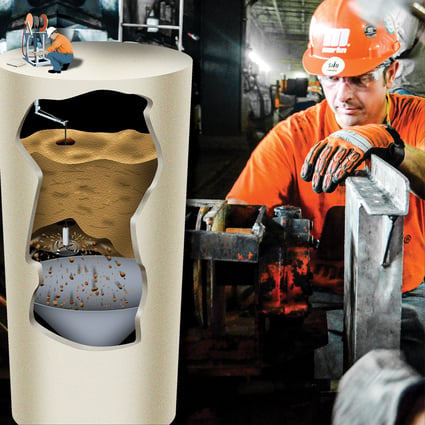

Are you experiencing less than ideal conditions in your silo, bin, hopper, or storage vessel? If you are seeing outside indicators such as off-center loading, discharging in chunks, more frequent fill cycles, and/or the need for pounding and poking to start material flow, chances are there is more going on inside than is visible to the eye.

Typical Problems Inside

Over time, bulk materials get compacted inside silos and large containers and it is necessary to remove buildup from interior walls and break up accumulated material. Vessels should be cleaned without putting workers in harm's way and without damaging container walls.

Scrape the Sides

Look familiar? The image on the left is something I struggle with quite frequently (nothing beats a good ol' PB&J sandwich). I'm sure many of you can relate to the frustration when you are ready to indulge in peanut butter and you spend more time scraping the sides of the jar than it takes to eat it. The image on the right is something our customers struggle with frequently as well. That picture is what keeps me on the phone most days, trying to get our crews out to sites to help break down built-up material and regain storage capacity. Just like it takes some time and work to get all of the sticky peanut butter out of the jar, a silo/bin/hopper/vessel requires attention to completely evacuate all material - which also can be sticky, wet, compacted, and stubborn.

Since we are on the topic of food, it got me thinking about a recurring annual cleanout we do. Most people I talk to don't realize we perform silo cleanout in the food industry. Andy's Seasoning shoots us an email stating it's that time of year again! And we hit the road. The cleanout always consists of a 3-man crew as it is a confined-space job. There are two silos to clean, the total cleanout time is about one day. The buildup on the roof and walls at this site gets particularly nasty when the material comes in contact with moisture.

Anytime and Anywhere

Customers can choose the frequency and the method to how they approach silo cleaning. Some prefer to do like Andy's Seasoning and contact us when they are ready. Some wait until there is an emergency and they've had to stop production. This is not as efficient for some operations but we do provide 24/7 emergency service for those needing immediate assistance. Some set up a scheduled recurring cleanout so they don't run the risk of a completely blocked silo.

Benefits of Silo Cleanout

PREVENT HAZARDOUS CONFINED SPACE ENTRY

Keep your personnel out of the vessel. Silo cleaning crews are OSHA and MSHA certified for confined space entry.

RISK-FREE FOR YOUR VESSEL

Effective system and experienced specialists clean without damage to walls, bottoms, or linings.

IMPROVED CLEANING TECHNOLOGY

High-performance cleaning system removes more material per hour and reduces time on your job.

NO OUTAGE REQUIRED

Many facilities stay in operation during vessel cleaning.

TURNKEY SERVICE

Your staff can get on to other duties; our fully equipped rigs bring all the personnel and equipment required.

SATISFACTION GUARANTEED

If not satisfied after one full shift, our crew will head out and you will not be charged.

Silo cleaning eliminates the need for confined space entry and enables the material to be recaptured and used in most cases. Technicians use remote control equipment from the top of the vessel to safely restore flow.

However you choose to ensure your storage vessels are in good operating order is up to you. We are here to help remove buildups, reclaim lost material, restore flow rates, and recover design capacity.

comments