By Don Papini on Dec 20, 2019 4:00:33 PM

When a primary cleaner is applied correctly and you still see residual material left on the belt, you should start thinking of applying secondary and tertiary cleaning systems.

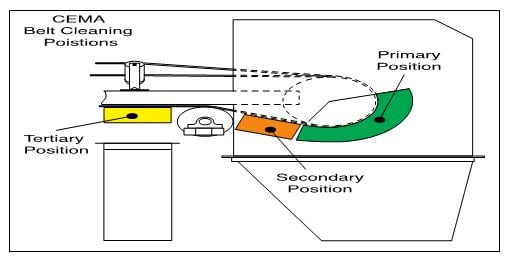

It’s not uncommon to use a primary belt cleaner to eliminate carryback from a belt. It’s also not uncommon for primary cleaners to not fully clean a belt or meet the desired results. In fact, when working with some materials and conditions, primary cleaners only eliminate about 50% of the carryback. When a primary cleaner is applied correctly and maintained properly on a belt surface in decent condition and you see residual material left on the belt, you need secondary and/or tertiary cleaning systems

Secondary and tertiary cleaners are often very effective at cleaning belts with difficult/stubborn carryback. These systems are installed with the cleaning point 2-3” after the belt leaves the head pulley. This area is typically where the belt will be at its flattest which makes it a good surface to clean. It also gives the belt some resistance from the pulley without pinching the belt between the blade tips. Obstructions may prevent the installation at this location. If so, a hold-down roll may be required to flatten out the belt further away from the head pulley, re-creating that desirable 2-3” location. The secondary and tertiary systems are generally full-belt width cleaners. Best practice is to match material path on the primary belt cleaner because of the wear characteristics of the typically-used urethane blades. Secondary and tertiary cleaners with tungsten carbide blades wear differently so they should be close to full-belt width.

Picking the proper belt cleaner and installation location are just as critical to the performance of these systems as the primary cleaner mentioned above. Routine maintenance including proper tensioning is also a critical step to ensuring maximum belt cleaning performance and efficient maintenance planning.

comments