By Todd Swinderman on Aug 14, 2020 8:00:00 AM

Conveyor belt systems are the lifeblood of a wide range of bulk material handling operations, including: mining | coal | ore processing | aggregate | cement

Modern systems are being tasked with moving greater volumes of cargo -- at higher speeds -- than ever before. Yet, the common practices in conveyor specification and design are out-of-date compared to the current expectations for safe, serviceable, and reliable conveying of bulk materials with minimal fugitive material.

Belt conveyors are often abused, whether through overloading, overuse, or neglect (or a combination of the three). It’s almost as if designers and manufacturers have done such a good job of providing very robust systems that continue to operate under all sorts of adverse conditions that conveyors are approaching the point of being considered a commodity which can be purchased by the pound rather than a carefully engineered system of hundreds of different components working together.

Many view conveyors as fairly simple equipment that merely transport bulk solids from Point A to Point B at a prescribed rate. In reality, they are complex systems that interact with virtually all major processes, and short cuts taken in the design and specification stages will have dramatic and far-reaching effects on safety, productivity, and the environment. Many decisions affect the initial and future performance of a conveyor system, with leading trends that include designing for lower risk, greater sustainability, and reduced life cycle costs.

Unfortunately, purchasing on lowest price rather than life cycle cost has become the norm. But the practice is seriously flawed -- often transferring funds for necessary design elements from capital expenses to the operating budget -- because the low-bid design cannot be cost-effectively maintained and modified to suit changing needs and conditions or the required funds to address shortcomings in the original equipment are never made available.

The results of poor specifications, designing to meet price goals, and moving around funding all contribute to numerous and expensive problems, such as inefficient operation, accidents, pollution, and litigation that can persist over the lifetime of the conveyor. To help facility owners and plant managers avoid the pitfalls of buying only on purchase price, experts have compiled a list summarizing ten of the most common design choices likely to result in a conveyor that is less safe, less clean, and less productive over time.

10 Common Mistakes

1. Not Knowing the Bulk Material

For decades, it has been common practice to use only the bulk density and angle of repose to describe a bulk solid. The Conveyor Equipment Manufacturers Association (CEMA) receives an untold number of requests for bulk material properties that can just be looked up in a table, as if every material variation can be effectively captured in a textbook. But there can be significant problems with this approach.

A simple example of the dangers can be found by considering a very basic requirement: tonnage. The primary purpose of the conveyor is to move X tons per hour from one place to another. If that one goal isn’t effectively achieved, all other requirements are secondary. But CEMA Standard 550: Properties of Bulk Solids has eight different bulk density listings for coal, ranging from ~600 to 980 kg/m3 (37-61 lb/ft3). That represents a large potential variation from the average bulk density: ~790 + 190 kg/m3 (49 + 12 lb/ft3). So, designing a system to accommodate the average value means that throughput could be over- or under-designed by +25%.

Further, the angle of repose for these eight coal listings varies from 27- 45°, a possible variation of +9° from the average. Designing the slope of hoppers or chutes based on the average value could mean that the bulk material doesn’t flow at all, or it might flow so freely that it can’t be adequately controlled by the chute geometry.

A typical set of tests to characterize a particular bulk solid costs about $30,000, while the estimated cost for system downtime is around $1000 per minute. Over the lifetime of a conveyor system, if just one plugged chute can be avoided - the testing will have paid for itself.

Similar arguments can be made for many other values that are critical to reducing future operating costs. For example, lump size and the percentage of fines are often misrepresented in a request for bid; the result can be ongoing disputes over contract performance.

Recommendation: Test samples of the actual bulk solid to be conveyed under the full range of expected moisture content and consolidating pressures, and use this information to design the conveyor system.

2. Loading on the Transition

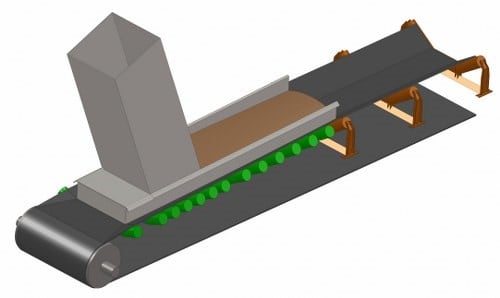

A common “trick of the trade” to meet price targets is to reduce the overall length of a conveyor by loading where the belt transitions from flat to troughed. Another approach to shortening the overall length of the conveyor to meet price targets is a design technique known as half-trough transition. When the practices of loading on the transition and half-trough transition are used in combination, the result can be increased belt wear, chute wear, and spillage.

Reducing the distance at both the loading and discharge zones by a meter or more of conveyor length can result in a savings of $15,000 to $20,000 per conveyor. Additional savings may be found in the reduced size for the building that houses the conveyor.

But these cost-saving measures have a price. Operating problems begin immediately with many designs that incorporate loading on the transition and/or using the half-trough transition. The primary issue is fugitive material -- that is, spillage and dust. In its transition from the flat tail pulley to the first full trough idler, the belt is a hard-to-model, complex 3D surface that varies based on belt tension (caused by variations in loading). It’s virtually impossible to accurately model this surface; consequently field-fitting of the chute to the belt line is required, which adds to the cost. A common rule of thumb is that it costs 10 times as much to do field fabrication as shop fabrication.

When loading on the transition and/or using the half-trough transition “tricks” in a design, the result is a chute that starts out parallel to the belt in the transition and then must form a convex curve to follow the belt when fully troughed. This flexure creates an entrapment point for fines that quickly wears the liner and skirt seal, eventually grooving the belt. The characteristic “half moon” wear area of the liner and skirt above idlers in the region where the loading is most turbulent leads to the escape of large quantities of fugitive materials that must be cleaned up – often by hand.

The $15,000 to $20,000 savings quickly evaporates in cleanup costs, more frequent maintenance of the seal and liner, and reduced belt life.

Using a full-trough transition design and waiting to load the belt until it is fully troughed can minimize negative effects.

Recommendation: Use the full-trough transition distance recommended for the belt and belt width. Start loading after the first full trough idler.

3. Using Minimum Pulley Diameters

The diameters for the conveyor’s main pulleys are usually selected based on the minimum recommended by the belt manufacturer for the life of the belt and splice, based on belt tension. Generally, no recognition is given to the concern that these pulley diameters may be too small to allow other components to function properly. When smaller drive pulleys are used, it often necessitates the use of snub pulleys to increase the wrap angle so there is sufficient friction to drive the conveyor. To increase the wrap, the snub pulley must be close to the drive pulley, which limits the space available for cleaning the belt at the head pulley and often leads to severe buildup on the snub, which is the first rolling component to contact the dirty side of the belt. When smaller main pulleys are used, there is often inadequate space between the top and bottom runs of the belt for accessories that are critical to protecting the belt and maintaining good tracking.

Recommendation: Best practice is to select a pulley diameter that is at least 600 mm (24-inches) diameter or one size larger than the minimum recommended by the belt manufacturer.

4. Lack of Access

The examples of lack of proper access in many conveyor designs are so numerous that an entire article could be written just on this topic alone. Conveyors are often placed in enclosures or tunnels where one side is so close to the wall that there is no room for a maintenance person to shuffle sideways along the conveyor.

Access doors may be located in odd places that allow a minimal view and are so small that no inspection or maintenance can be done through them. Conveyors may be so close to the floor that there is no room to clean under the conveyor. Further, the location of platforms and drive components around the head pulley are often so misplaced that it’s impossible to reach components for proper inspection or maintenance.

Recommendation: Follow CEMA recommendations for access and clearance, as detailed in Belt Conveyors for Bulk Materials, 7th edition.

5. Covering Key Components with Piping and Conduit

The support structure of the conveyor makes a convenient rack system for mounting electrical conduit and the piping for plant air or water supply. It’s a common omission not to control the location of conduit and piping runs on a conveyor structure. The fact that this piping and conduit often impedes the installation and service of critical components such as belt wander switches, belt cleaners, plows and return idlers is well recognized.

The conduit and piping rarely need maintenance or relocation, while the components that surround it typically do need frequent inspection and service. To add insult to injury, these plumbing runs are often on the side of the conveyor where there is a walkway, supposedly installed to provide access.

Recommendation: Specify that conduit and piping runs not be allowed to block or impede access to critical components along the conveyor. At the head and tail pulley, all conduit and piping should be installed with flexible conduit drops to connect components.

6. Insufficient Edge Sealing Distance

The free belt edge outside of the skirtboards in the loading zone of a conveyor is called the edge sealing distance. The CEMA standard is based on the distance between the inside dimensions of the skirtboards being equal to 2/3 the flat belt width, which does not account for the toughing angle. The European standard is based on a formula for free belt edge. Neither of these current standards provides adequate edge distance to accommodate the belt tracking and sealing systems required to meet today’s requirements for dust and spillage control. The free edge distance should be based on the distance needed to properly seal the belt. The allowance for belt tracking is based more on the structure and pulley face widths and does not vary significantly with belt width.

Recommendation: The free belt edge available for sealing the belt and allowing for belt mistracking should be at least 115 mm (4.5 inches), regardless of belt width.

7. Poor Chute Design

Chute design has improved in recent years through the use of Discrete Element Method (DEM) modeling programs, but many chutes are still drafted rather than designed. However, if the properties of the bulk solid are not properly identified, the DEM results can be worse than using the old “rule of thumb” design methods.

Even if the bulk material is well specified, the approach to designing the structural support of the chute and the pulleys is based primarily on ease of fabrication and installation, rather than designing for the intended use, which requires proper access. Usually an A-frame type of head pulley support, with one leg vertical, provides better access than a table frame design.

Recommendation: Test the bulk solid and use the properties that represent the worst-case flow to design the chute using DEM. Design the structure so that it does not impede access to critical components, yet allows adequate access for maintenance as well as future upgrades.

8. Inadequate Belt Cleaning

One can only conclude that as dust and spillage requirements tighten over time that more sophisticated belt cleaners in larger numbers will be required. Often an inadequate number of belt cleaners or cleaners with too low a duty rating are specified. In addition, the space that is provided in the design may not allow the proper installation and service of belt cleaners.

Suppliers are pressured to meet price goals and end up providing equipment that they know will not meet expectations. But the game is to make the specification vague enough so the supplier can be pressured with a choice: “meet the price or we will put in a simple design and let the customer deal with the problem.”

Recommendation: Include belt cleaning performance specifications in the conveyor requirements. Allow adequate space for scavenger conveyors if the head chute design is such that at least 3 cleaners cannot fit in the available space and the carryback can be captured in a dribble chute with near-vertical walls.

9. Substituting Speed for Belt Width

Conveyors are routinely designed to travel at speeds as high as 7.5 to 11.5 m/s (1400 to 2300 fpm). Some industries have established maximum transport speeds to limit degradation of the bulk solid and/or control dust. While these practices have their roots in practical experience, they are often stretched to meet price goals. Dust and spillage are directly related to belt speed and tonnage, while wear is a function of the square of the bulk material stream. So the trade-offs between width and speed should be considered carefully.

Recommendation: Follow the suggested maximum conveying speeds listed in CEMA’s Belt Conveyors for Bulk Materials, 7th edition. Underrate or oversize the conveyor.

10. Failure to Allow for Upgrading

When the topic of upgrading a system is brought up, the normal assumption is that the belt speed is being increased. Other than the drive and a few other components, the only thing that supposedly gets upgraded is the tons per hour output. Upgrading by changing the speed alone often results in a throughput decrease rather than an increase, due to pluggage problems created by the change in material trajectory or the existing chute cross-section creating a flow restriction. Many designs leave no room for even modest upgrades or additions. With minimal effort in the design phase and at little or no additional fabrication or installation cost, some flexibility can be built into the system for performance-improving upgrades.

Recommendation: Use standard components to meet price targets, but allow space in the design for problem-solving upgrades to meet production/cost targets.

Conclusion

Deciding to ignore these problematic areas, and purchasing solely on price, usually results in less throughput than specified, higher operating and maintenance costs than budgeted, and reduced safety. Each of the issues, if addressed in the specification and design stages, can easily be justified based on life cycle costing and cost avoidance. Once these design problems progress to the fabrication, installation, and operation stages, they may or may not be correctable, at substantially more cost than if they were addressed and funded early in the project.

comments