By Lee Mueller on Feb 3, 2020 3:22:40 PM

In my role at Martin, I travel to different sites and lead Conveyor Operations and Maintenance workshops, and I come across various circumstances/confusions in the bulk material handling industry. One frequently being the misunderstanding of chute wall skirting's role.

I really can’t recall a single workshop where most of the participants understood the proper role of chute wall skirting. Fact or Fiction...skirting is designed/intended to retain material inside of the chute?

Fiction!

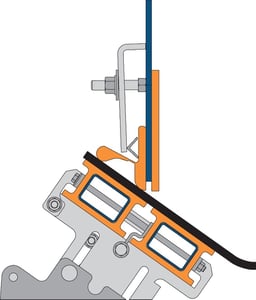

Skirting is NOT intended to retain material. It is intended to retain air inside the chute as a means to control dust and stop it from escaping. Does the skirting provide some form of product retention, yes to a small degree, but a proper wear liner must be used in order to successfully contain material. Skirting will blow out, wear, or fail without a proper wear liner installed to act as the material dam.

As material is loaded onto the belt in the load zone, product is dropped onto a troughed belt. When material settles onto the belt, some of the material will be pushed up the sides of the chute wall. It is often expected that the chute wall and skirting should contain this material, that’s the misunderstanding. The wear liner's job is to contain the material. The skirting's job is to contain the accompanying air.

As material is loaded onto the belt in the load zone, product is dropped onto a troughed belt. When material settles onto the belt, some of the material will be pushed up the sides of the chute wall. It is often expected that the chute wall and skirting should contain this material, that’s the misunderstanding. The wear liner's job is to contain the material. The skirting's job is to contain the accompanying air.

Keep Coffee In Your Cup!

A similar scenario is pouring coffee (or beverage of choice) into a cup. Have you ever poured it too fast? If so, it will hit the bottom, push to the side, and splash out of the cup. The same thing happens in the load zone. As the product pushes to the side of the chute, if the wear liner is not properly positioned or installed, it will blow past the skirting, resulting in spillage.

comments