By Chelsea Blake on Jan 22, 2021 2:36:00 PM

Just before I went to check the chicken coop for eggs for the day, I noticed the 800# call line was ringing. I don't typically answer that line, other more knowledgeable people do! Wouldn't you know it that the one time I do, it was a totally uncommon and unique inquiry. One I was not EGGSpecting. 😅 I found myself on the phone with a chicken farmer. Being a self-proclaimed chicken farmer myself or "mom of chicken farmers," I felt an immediate connection to this guy and the problem he was experiencing...we were like birds of a feather (ha - I crack myself up)!

Transporting Chicken Waste

After we chatted a bit, he explained his operation to me and the setbacks he was dealing with. He owns 120 million chickens. That is a lot of chickens....and a lot of chicken s&*t. He runs 30 conveyors that transport chicken waste to be sold as fertilizer.

photo credit: Matthew T. Rader

Given the nature of the material he conveys, he experiences a lot of material carryback on the belts. Chicken waste that remains on the belt equals less waste being transported and sold, therefore reducing productivity and profit. This carryback also creates labor and safety issues. Manual methods to remove and cleanup carryback are labor-intensive and extremely dangerous as they put workers in close proximity to moving conveyors and pinch points. Spending maintenance hours shoveling up carryback is not an efficient use of time and energy.

Different Material, Same Problem

Carryback is a problem that plagues most material handlers, regardless of the type of material itself. Whether coal, sand, gravel, grain, pulp & paper, or chicken waste....they all have the tendency to stick to the belt past the discharge point, requiring more attention and work.

Removing Chicken $h*T From Conveyor Belts, Chicken Coops, & Eggs

When washing eggs, we sometimes have trouble completely removing the chicken waste (it can be quite stubborn and sticky) in order to get them clean and ready to be sold. It takes some extra time and effort. I can only imagine what a chore it is to remove it from 30 conveyors.

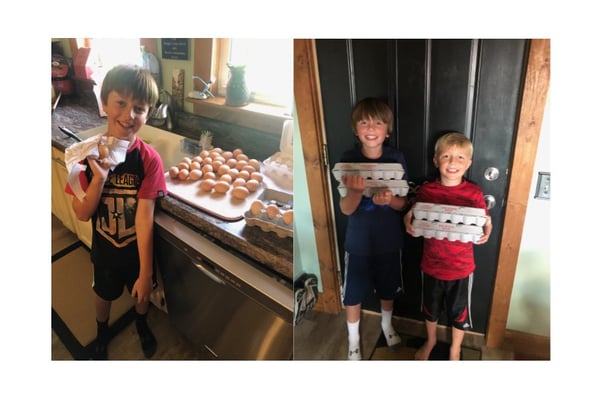

Since we are a small, backyard chicken operation, we obviously rely on manual labor to clean out the chicken coop. The boys spend a lot of time shoveling chicken waste out the coop...on average, they spend a few hours a week to clean out a small 10' x 14' coop. Good thing we have FREE labor. I can see how quickly this large-scale operation's carryback got out of hand!

My oldest even got a chicken leash for Christmas to ensure the wellbeing and health of his chickens! Not sure that was in the budget. Just like he is worried about his chickens and their health, the managment at this operation was worried about the safety of its employees. Requiring employees to do manual cleanup of the carryback is dangerous, and they needed a solution.

Profit

Runnning cleaner, safer, and more productive operations is of the upmost importance. But sooner or later, conversations start turning to profit as well. Carryback has a big impact on cleanliness, safety, productivity, and profit.

Just like in large operations, the boys need to think of profit too and how to improve their operation. These farm boys were happy to show some of their chickens at the county fair. Their profit wasn't very much ($4 for best in show) but they earned bragging rights!

Production Interruptions

As production in material handling is affected when there are inefficiencies or breakdowns, our small egg business experiences the same issues. Meet our "inefficiency" or "breakdown" on the right, better known as Hunter who has contributed to reducing our coop occupancy from 13 to 7. Bad dog! 🐕

Carryback Removal

As we immediately started to correct and resolve our operation's inefficiency, Hunter the chicken killer...this chicken farmer was beyond ready to remedy his carryback situation. I explained that even though his industry and application was one I hadn't heard or dealt with before, I was confident that our belt cleaners could stand up to the challenge. As I mentioned before, carryback is carryback.

A  paired with a

paired with a  is one of the most effective ways to remove carryback. And to suit a variety of applications (even chicken s&*t), we have an entire color-coded line of urethane that is poured in-house and formulated to perform in specific environments.

is one of the most effective ways to remove carryback. And to suit a variety of applications (even chicken s&*t), we have an entire color-coded line of urethane that is poured in-house and formulated to perform in specific environments.

After our phone conversation, this guy was wondering "why am I dealing with this chicken s&*t?! Bottom line is, you don't have to deal with carryback - resolve it!

comments